Project List

We are excited to share the journey of our leadership team, whose career has been defined by a remarkable involvement in various projects that has left a lasting impact. Throughout Albert’s professional trajectory, they have spearheaded numerous initiatives, demonstrating a relentless commitment to innovation and excellence.

From pioneering ventures to transformative endeavors, albert has been at the forefront of shaping industries and driving positive change. Their visionary leadership and hands-on approach have been instrumental in the success of each project they’ve undertaken.

As we delve into the story of our founder and their remarkable journey, we make list of some these projects and products:

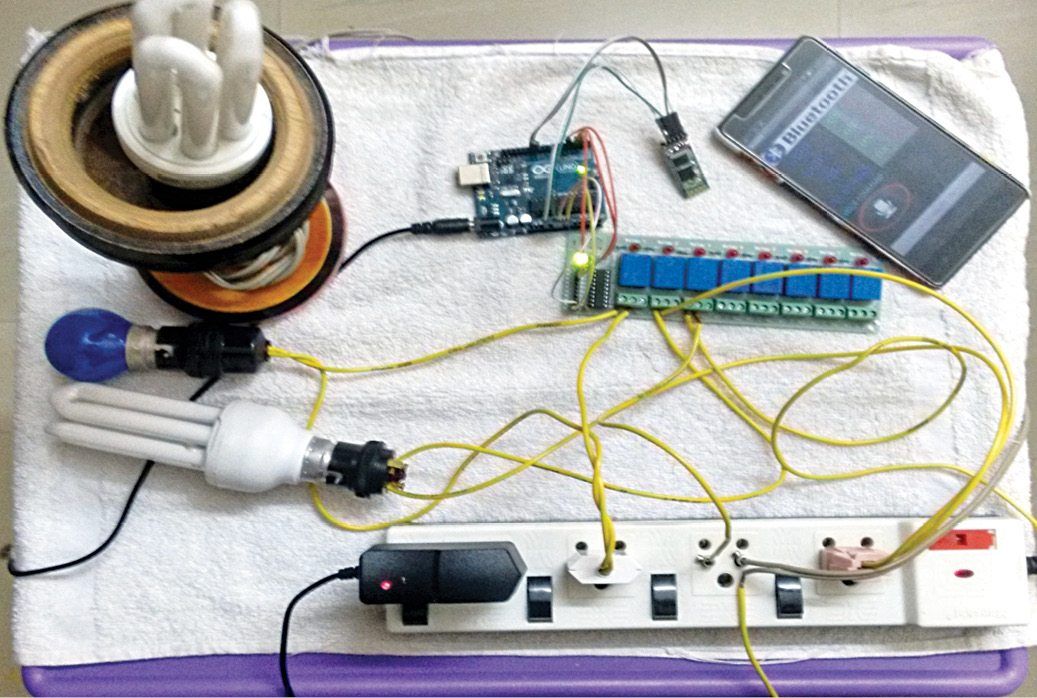

Electrical Projects

- Hydrogen pump controler

- Startup consulting advisor

- Consultant for 2000 AMP- MCC panels – power and control

- In charge of getting UL Certificate for Electrical Panels

- Design Over 100 Industrial Electrical / Control Panel for OEMs includes VFD, PLC and HMI with different voltages

- Design the Electrical, Controls and Safety system for different projects and products

- Designed an electrical system for Aircraft Refueling Station includes electrical systems, pumping stations, power distribution, MCC, lighting, single line diagram, power interconnection diagram, location and layout, grounding area and lighting

- Design the CAD shop for MCC and Allen Bradley PLC Panel with wireless, network and HMI

- Design the new Electrical and Control panel for new devices

- Modify, Retrofit, and develop the existing electrical and control system to reduce the cost of production and maintenance

- Design the Plug n Play Motherboard for Industrial devices

- 10. Design MCC, Control panel, PLC panel, main and Sub panel

- Developing electrical and control diagrams for PLC, HMI, and VFD for existing motor control centers (MCCs).

- Arc Flash Study and recommendation Consulting for commercial building

- Arc Flash Calculation for MCC. Electrical panel

- Medium voltage power system design, generator, and distribution

- Designing and managing electrical projects such as Data Canter, Hi-Tech and commercial building, and K-12

- Hardware design for electrical panels, electrical, building automation system, instruments, networking, safety equipment

- Familiar with CE, CSA, UL 508 A, UL489, NFPA70, ISA, TQM

- And more n more

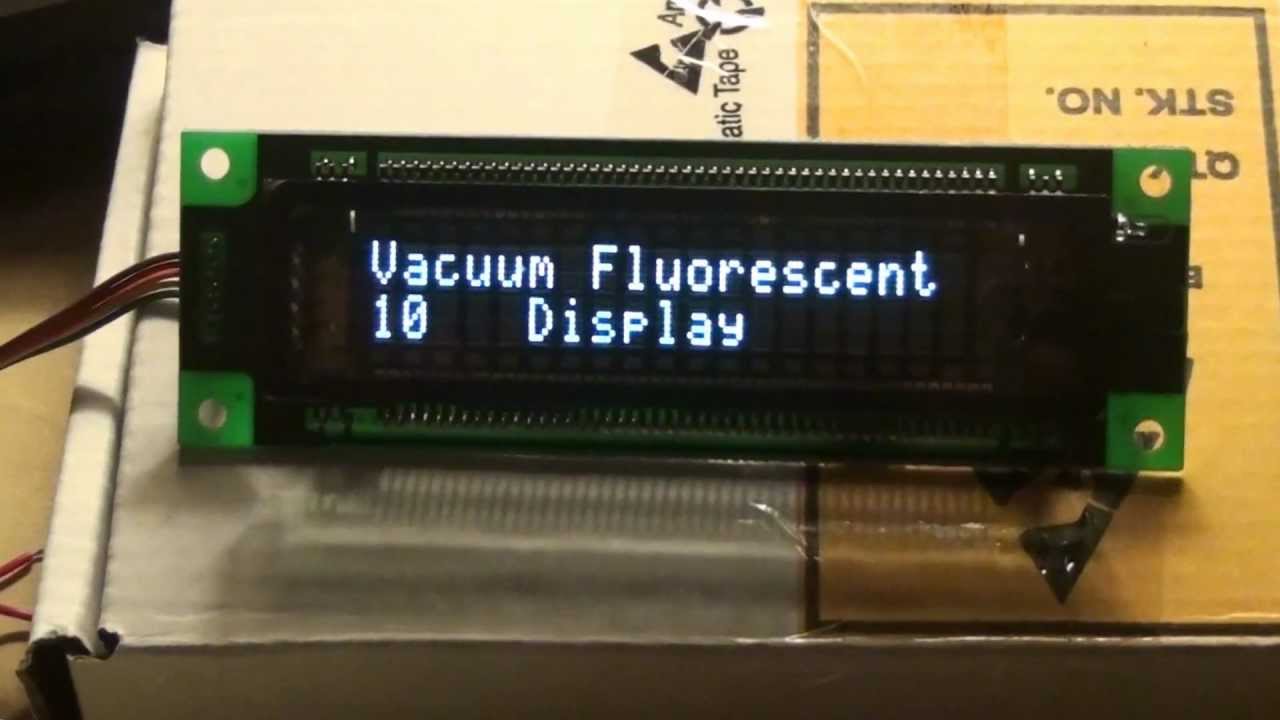

Controls/PLC Projects

- Lead Controls System for process and equipment in different industries

- Programming PLC and HMI with different software such as Studio5000, RSlogix, TIA Portal, Sysmac, GIT from Siemens, Rockwell Automation, Allen Bradley, Omron, Mitsubishi and more

- Design the Control Narrative and P&ID, Flowchart

- Control logic: design and draft SAMA logic, loop diagrams and P&ID, PLC.

- Design the HMI Application with WinCC, FactoryTalk, Wonderware, iFix, Ignition and others.

- Program the PLC and HMI with Wonderware programmed and designed the new control system for the production line

- Designed the PLC Data plan exchange between PLCs' , HMIs' and network

- Programmed control system with PLC and HMI for cement block production line.

- Designed Profibus fiber-optic network and supervised commissioning.

- Programmed PLC system for high-speed web printing the system with 100,000 impressions per hour

- Teaching PLC; TIA Portal, and HMI applications; Factory Talk, and WinCC

- Design the controls and electrical systems include Safety assessment, hardware and software design, programming, and commissioning

- Process, SAMA, remote control, radio, loop diagram, Visio, Solid Work, and other related software

- Design the control system for testing equipment

- Design the control system for the press machine with safety PLC.

- And more n more

Automation Projects

- Consulted and designed automation systems for automobile parts, cement, food and beverage, paper, and other

- Designed over 120 Industrial Automation System for different industrial machine and production line

- Supervised Electrical shop for building MCC, controls and PLC panel

- Reviewed and modified hardware PLC drawing “Issued for Construction” design drawings

- Drawing submittals of control panel components, instrumentation

- Analyzed plant process design, Motor Control Center (MCC), PLC panel, and control panel drawings

- PLC program design and modified for solving the Thermal Oil problem

- Design the SCADA System, PLC and HMI for water and wastewater projects

- Supervising field instrumentation and electrical technicians during the installations and commissioning

- Design Control Systems include PLC, HMI, VFD, Servo, Encoder, Motion Control

- SCADA system for generators, distributions, substation, and other electrical equipment.

- And more n more

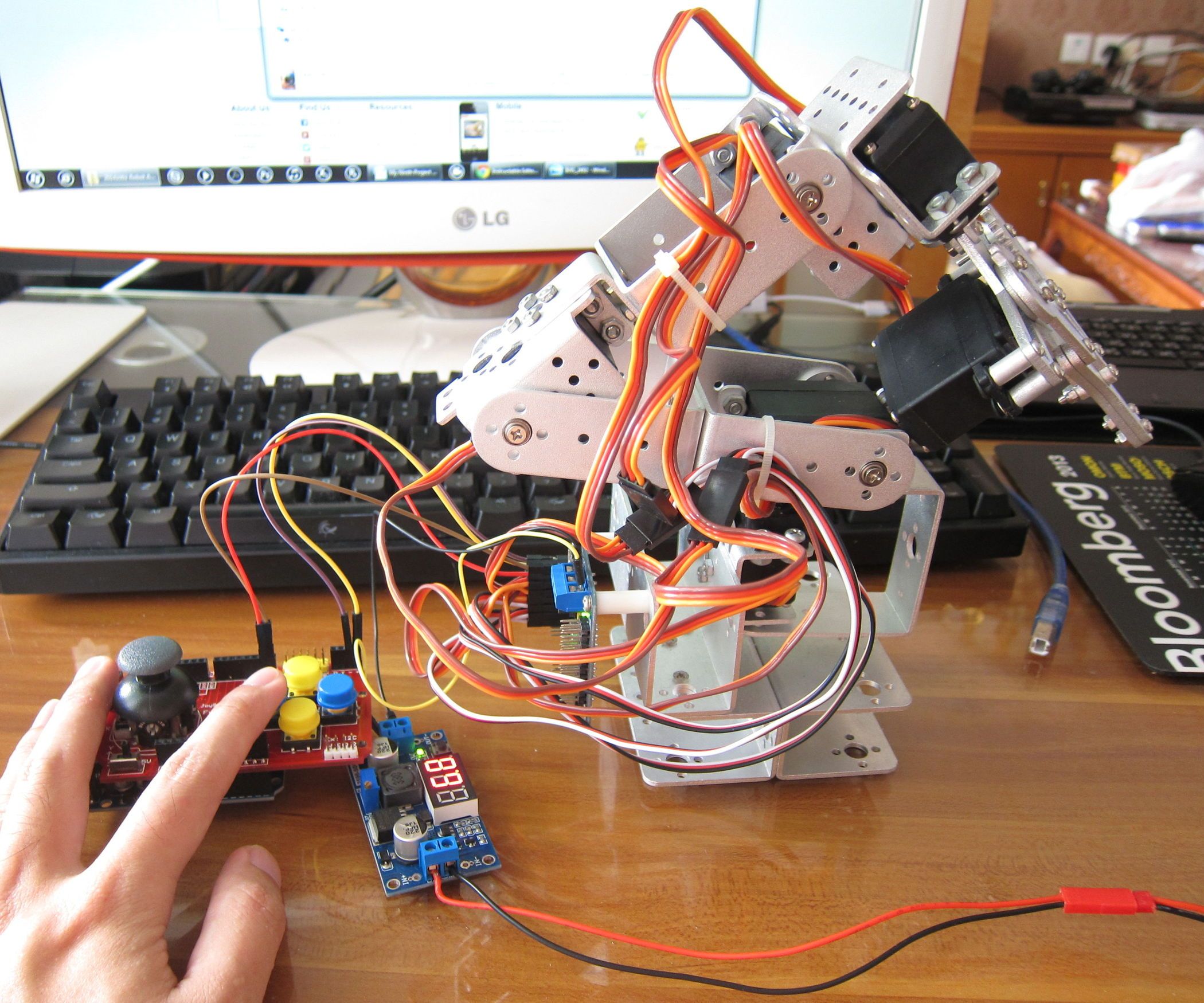

Robot Projects

- Design the Revolution of Controlling the Robot

- Design and Lead Electrical, Controls and Robot System for Alpha and Beta unit systems with special design

- Designed the Control System for Gantry Robot and fully automated stations with Robots (Pick n Place, Vision), PLC, HMI

- Designed the fully automated production line with Robots; Pick-n-Place, Vision, Lazy Susan Tray, and Conveyor, Gantry

- Design the Control System for Battery Assembly Power Pack for Electrical Vehicle

- Robot Controls Engineer for Battery Production Line for EV (Electric Vehicle).

- Design the control system for Battery’s testing station with Moving Robots and Moving Cart (AGV).

- And more n more

Startup Projects

- Startup Consulting the Robotics Application from Idea to Production.

- Design and Involved of Tests, V & V test process and UL and ETL

- Innovated, designed and build from idea to mass production few batteries system application for Light Electric Vehicle and mobility with Lithium-Ion Battery

- Involved a few NPI (New Product Integration)

- Design and write the specs for battery, motor, controller, BMS, electrical panel, control panel, component, and sensors

- Built the prototypes and simulation of the EV Battery application system to reduce the risk of failure

- Develop the Battery Management System (BMS) to control the EV system and increase its ability

- Involve with New Systems from Idea, Concept, prototype, texting, and New Products Development

- Strong hardware management and design engineering, controls, automation, and Robot projects

- Design the control system for Battery Assembly Power Pack for Electrical Vehicle

- Consulting in Hi-Tech, Electrical, and Controls Projects and PCB design projects

- Involved in various stages of the project: concept, prototype, testing, V &V testing, and Standard testing (UL and CE)

- And more n more

Green Projects

- Involved in Hydrogen Fueling Station

- Design the control system which minimized boiler sander dust and monitored and controlled the air flows within the furnace, steam and power demands, PLC, HMI, Networking plan with details.

- Analyzed and designed modification of OSB quality process from Log Ponds to Finishing to reduce waste time

- Design and install over 100 VFD for reducing the usage energy and be greener

- And more n more

VFD Projects

- Install different sizes of VFD for motors, and pumps to reduce the maintenance, saving energy and have more ability for controlling the speed and torque

- Troubleshooting the VFDs

- Teaching the VFD setting and coding

- Using different brand such as AB, Siemens, Mitsubishi

- And more n more

Management Projects

- Acquires resources for projects and processes, provides technical management of suppliers, and leads process improvements

- Develops and maintains relationships and partnerships with customers, stakeholders, peers, partners, and direct reports

- Provides oversight and approval of technical approaches, products, and processes

- Manages, develops, and motivates employees

- Leads proposal development

- Leads cross-site team in execution of schedule commitments

- Planning, designing, and overseeing projects, as well as managing finances and supervising one or more engineering teams

- Manages daily operations in the department responsible for the planning and engineering of an organization's systems infrastructure

- Ensures that hardware and/or software are designed and installed in a manner that meets the needs of the organization

- Monitors systems performance and provides recommendations as required

- Communicate with vendors, technicians, and other related suppliers

- Member of Production team and attended weekly meetings

- Oversee the engineering, service, and production department with over 28 engineers and service technicians

- Safety and Risk Assessment Consulting

- Lead the UL Certification for Robot applications

- Support other Engineer and management team, Team Members, Consulting in Robot, Controls, and Electrical

- Using the AutoCAD Electrical, Lucid, One shape, Jira, Slack, Confluence

- Manage the documenting the projects such as configuration, PLC and HMI configuration, instrumentation loop sheets, commissioning, tuning services upon completion of installation and compilation of an operator manual

- Documented existing PLC’s including schematics, P& ID analysis, logic diagrams, as well as utilized Auto CAD for I/O PLC S5 and S7 300, S7 400 diagrams

- And more n more

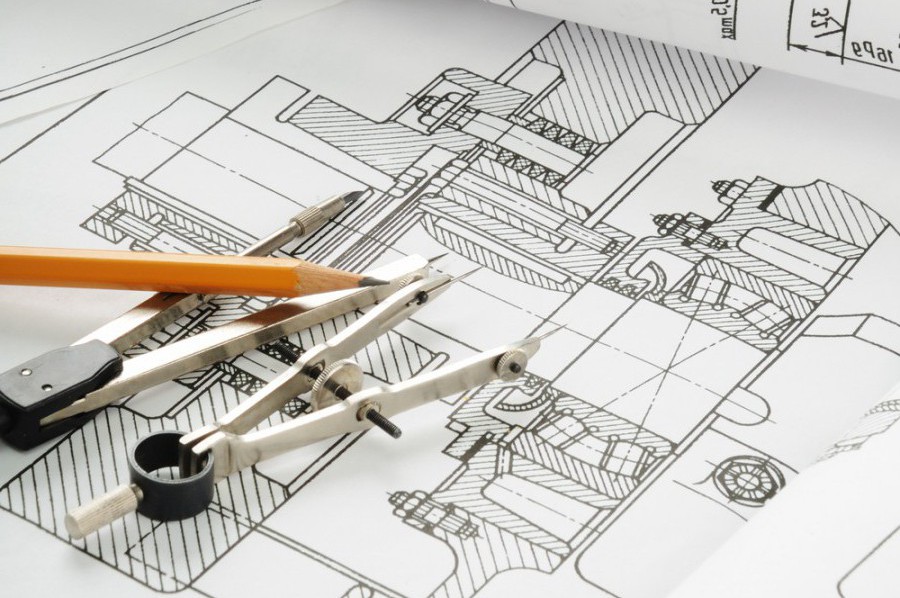

Drafting Projects

- Using AutoCAD for designing the electrical panel with chose electrical components, VFD, Soft Start, PLC and HMI

- AutoCAD Electrical experience for panel design

- Create an Electrical Drawing for existing panel

- Transferring the RED Mark to electrical drawing and generate new set

- And more n more

QC Projects

- QC – Quality Control the MCC

- Inspect the Electrical Drawing before release

- Create an Electrical Drawing for existing panel

- Inspect the Electrical Panel during, and after build before final inspection

- And more n more